BEST PRICE CLADDING GUARANTEED! - Call 01642 241777

#2 Best Seller

in Ceiling Cladding

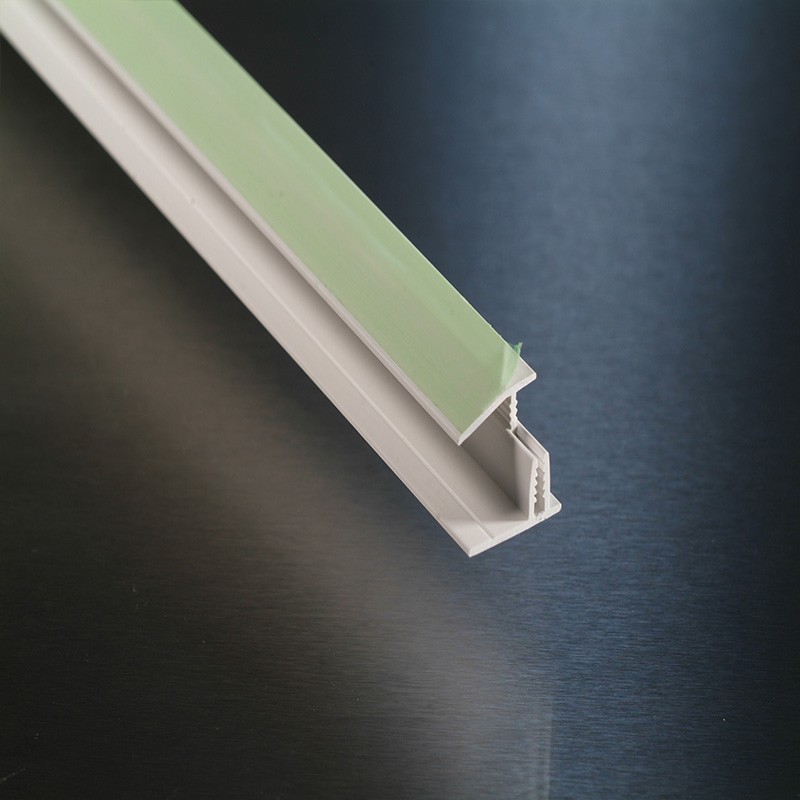

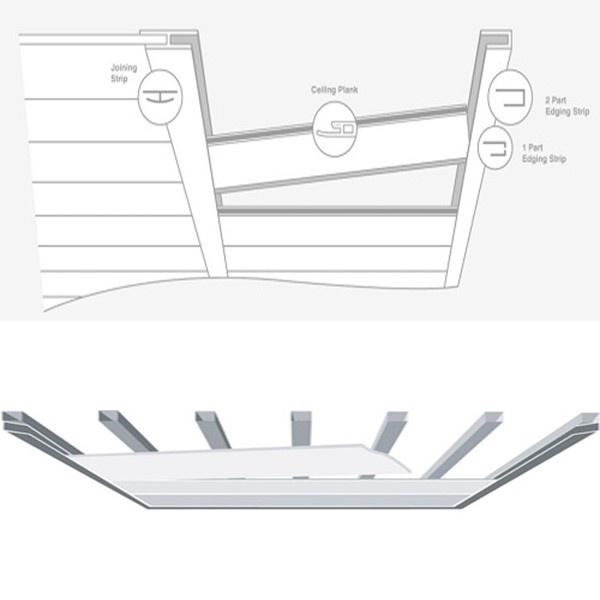

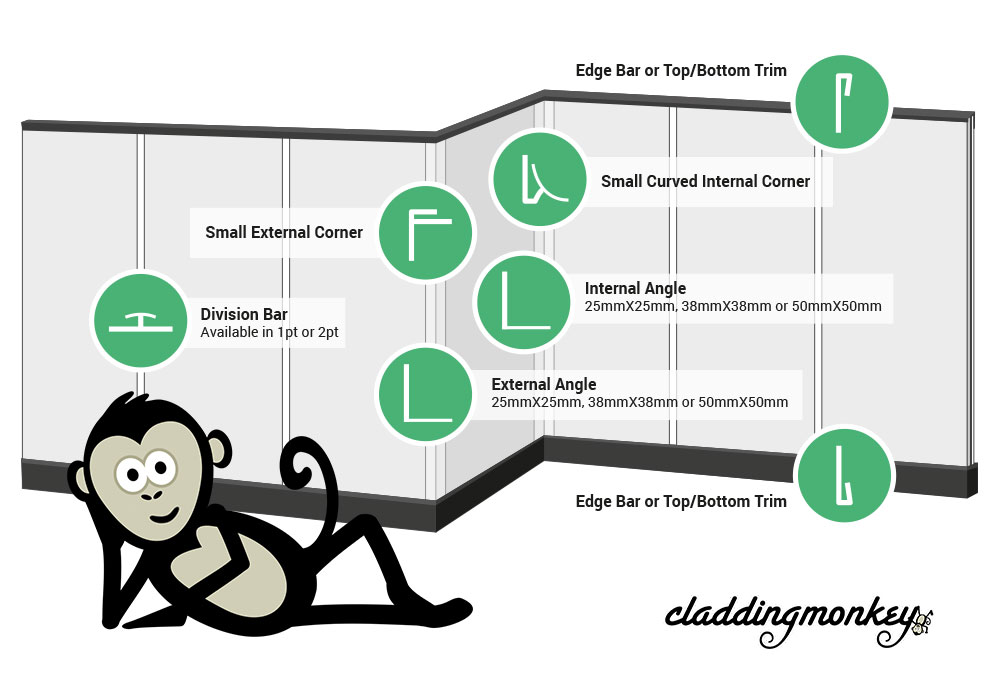

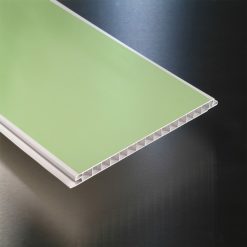

Hygienic Ceiling Plank Edge Bar (2part) | 5mtr length

From £23.75 (ex. VAT)

From £28.50 (inc. VAT)

need it tomorrow? order within

- Hygiene ceiling plank start or edge trim (2 PART) 5mtr

- Matching satin white plank finish

- Used as a starter trim or to finish cut or exposed edges

- Class 1 fire rating, food grade PVC

*Our most popular edge bar for ease of use/install