BEST PRICE CLADDING GUARANTEED! - Call 01642 241777

#7 Best Seller

in Adhesives

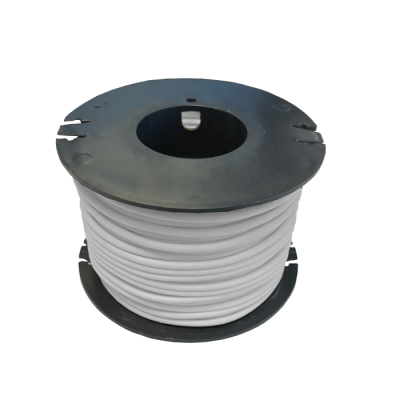

600ml Foil Adhesive Applicator Gun

From £35.00 (ex. VAT)

From £42.00 (inc. VAT)

need it Friday? order within

- 600ml high quality foil applicator gun by Everbuild

- For use with our 600ml adhesive foils

- DOUBLE the size of a standard cartridge gun

- SAVE time, SAVE money, SAVE waste

- What the trade use

*To be used to apply our 600ml foil adhesive.